Hami Hardware Store

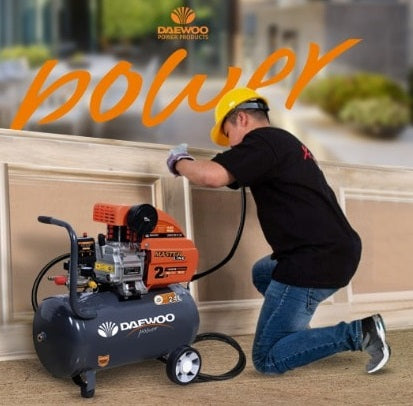

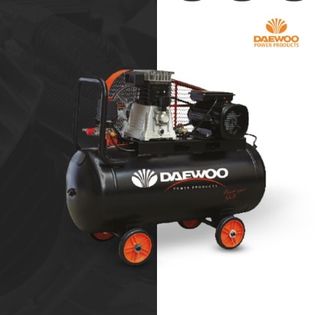

Daewoo Air Compressor 50LTR

Daewoo Air Compressor 50LTR

Couldn't load pickup availability

An air compressor is a versatile mechanical device that converts power into potential energy stored in compressed air. This compressed air can then be used for various applications across industries and everyday tasks. Air compressors are commonly found in workshops, manufacturing facilities, construction sites, and even for personal use in homes and garages.

Key features and considerations for an air compressor include:

-

Power Source:

- Electric Air Compressor: These are powered by electricity and are suitable for indoor use or areas with access to power outlets.

- Gasoline-Powered Air Compressor: Gasoline or diesel-powered compressors are more portable and suitable for outdoor or remote locations where electrical power might not be available.

-

Type of Air Compressor:

- Reciprocating (Piston) Compressors: These compressors use a piston-cylinder arrangement to compress air. They are available in single-stage and two-stage configurations.

- Rotary Screw Compressors: These compressors use two rotating screws to compress air. They are often used in industrial applications due to their continuous operation and efficiency.

- Centrifugal Compressors: These compressors use a rotating impeller to accelerate air and then convert its velocity into pressure.

-

Tank Capacity: The tank capacity determines how much compressed air can be stored. A larger tank provides more air storage, allowing for longer continuous usage without the compressor running constantly.

-

Pressure Rating: Air compressors deliver air at a specific pressure, measured in pounds per square inch (PSI) or bar. Consider the pressure requirements of your tools and applications.

-

Cubic Feet per Minute (CFM): CFM is the measure of the volume of air that the compressor can deliver at a specific pressure. Match the CFM output to the requirements of the air tools you'll be using.

-

Portability: Consider the size and weight of the compressor, especially if you'll need to move it around frequently.

-

Oil-Lubricated vs. Oil-Free: Some compressors require oil lubrication for their internal components, while others are oil-free. Oil-free compressors are generally easier to maintain but might have limitations in certain applications.

-

Noise Level: Compressors can be noisy, especially larger models. Look for models with noise-reducing features if noise is a concern.

-

Accessories and Attachments: Some air compressors come with a variety of attachments and accessories, such as hoses, air tools, and regulators.

-

Safety Features: Check for safety features like pressure relief valves and thermal protection to prevent overpressure and overheating.

-

Maintenance: Regular maintenance includes changing oil (if applicable), checking air filters, and ensuring proper lubrication.

Share